Smart Factories: The Next Industrial Era

The concept of smart factories represents a significant evolution in the industrial landscape, moving beyond traditional manufacturing to integrate advanced digital technologies. These sophisticated production environments leverage connectivity, data analytics, and automation to create highly efficient, adaptable, and responsive systems. By reimagining every aspect of the production process, smart factories aim to optimize resource utilization, enhance product quality, and accelerate market responsiveness, setting a new benchmark for industrial operations worldwide.

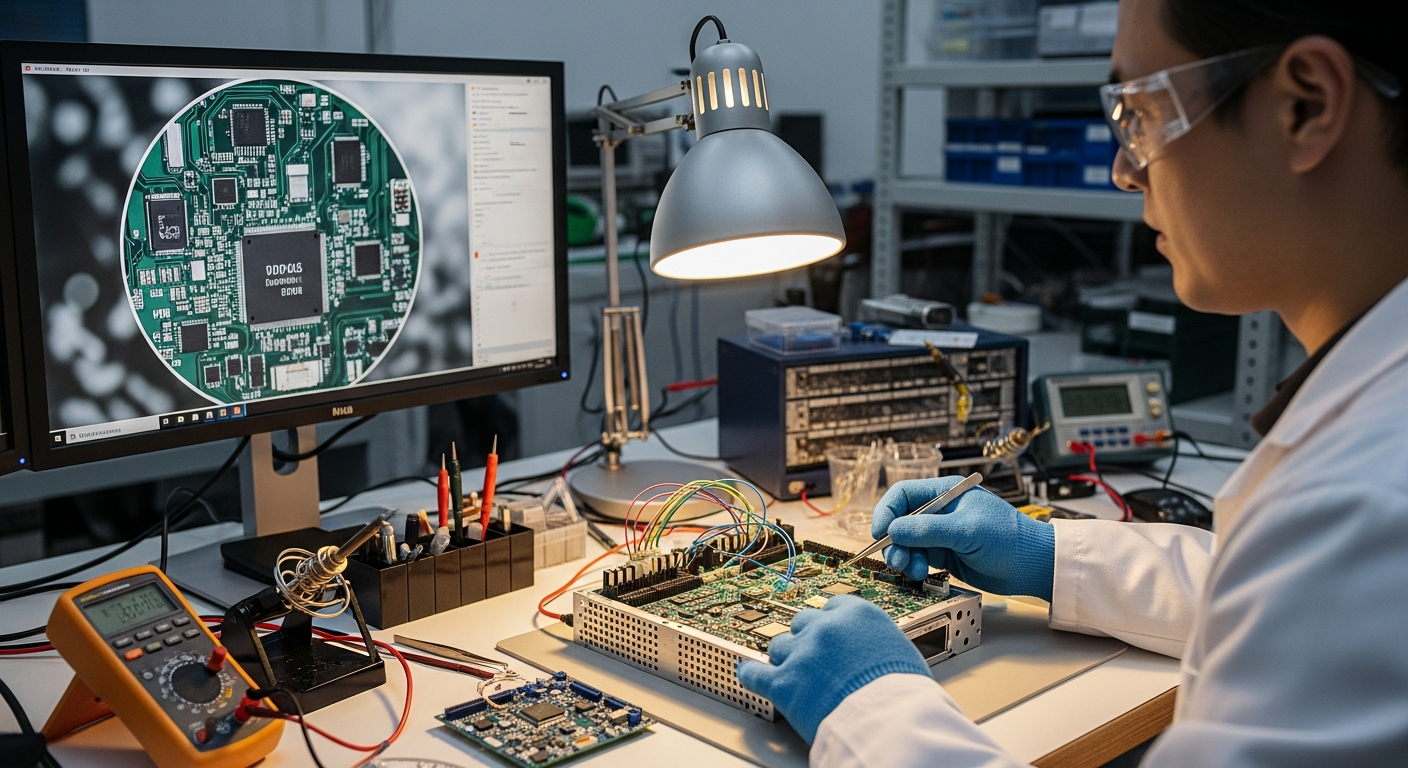

A smart factory is characterized by its extensive use of interconnected systems, real-time data, and advanced automation to achieve highly optimized production. At its core, it integrates the physical and digital worlds, often referred to as the convergence of Information Technology (IT) and Operational Technology (OT). Key elements include the Internet of Things (IoT) for device connectivity, Artificial Intelligence (AI) and machine learning for predictive analytics, and advanced robotics for automated tasks. These technologies enable a factory to sense, analyze, and adapt to changing conditions autonomously, leading to more agile manufacturing and production processes.

Enhancing Efficiency and Automation in Operations

Smart factories profoundly impact operational efficiency by automating routine and complex tasks, thereby reducing human error and increasing throughput. Advanced automation, powered by robotics and AI, optimizes production lines, ensuring consistent quality and faster cycle times. Real-time monitoring systems track every aspect of operations, from machine performance to material flow, allowing for immediate identification and resolution of bottlenecks. This proactive approach, often involving predictive maintenance, minimizes downtime and maximizes the overall equipment effectiveness across the entire manufacturing process, leading to substantial gains in efficiency.

Transforming Supply Chains and Logistics

The integration of smart factory principles extends beyond the factory floor to revolutionize the broader supply chain and logistics. Digital technologies provide end-to-end visibility, allowing enterprises to track raw materials from suppliers to finished products reaching global markets. Predictive analytics can forecast demand fluctuations and potential supply disruptions, enabling proactive adjustments to inventory and shipping strategies. This enhanced connectivity and data-driven approach lead to more resilient and responsive supply chains, capable of adapting quickly to market changes and ensuring timely delivery, which is crucial for sustained growth.

The Role of Data Analytics and Innovation

Data is the cornerstone of the smart factory. Sensors and connected devices generate vast amounts of information that, when processed through advanced analytics, provide actionable insights into every facet of operations. This digital intelligence supports continuous improvement initiatives, identifies areas for cost reduction, and informs product development and innovation strategies. By understanding patterns and predicting outcomes, businesses can make more informed decisions, refine their production processes, and develop new, high-quality products that meet evolving customer demands, driving enterprise development and competitive advantage.

Addressing Workforce Development and Sustainability

The shift towards smart factories necessitates a transformation in workforce skills. While automation handles repetitive tasks, human roles evolve towards oversight, data analysis, and strategic decision-making. Investing in workforce development and training programs is essential to equip employees with the digital and technical competencies required for these new roles. Furthermore, smart factories inherently promote sustainability. Through precise resource management, optimized energy consumption, and reduced waste, they contribute to a smaller environmental footprint. Enhanced safety protocols, often leveraging AI and IoT for hazard detection, also improve workplace conditions, ensuring the well-being of the workforce.

Future Outlook for Industrial Growth

The continuous development of smart factory concepts is setting the stage for significant industrial growth and strategic advantages. As technology advances, these factories will become even more autonomous, self-optimizing, and interconnected, forming vast networks of intelligent production hubs. This evolution promises not only increased efficiency and flexibility but also new opportunities for business models and global market expansion. Companies that embrace these innovations and adapt their enterprise strategy will be well-positioned to lead in the next industrial era, leveraging digital transformation for sustained success and resilience.

Smart factories represent a pivotal advancement in industrial capabilities, merging cutting-edge technology with traditional manufacturing to create highly adaptive and efficient production systems. By integrating automation, data analytics, and interconnected processes, they offer transformative benefits across manufacturing, supply chain management, and operational efficiency. The ongoing evolution of smart factories promises to reshape the global industrial landscape, fostering innovation, promoting sustainability, and driving significant growth for businesses worldwide.