Micromanufacturing: Revolutionizing Production at the Microscale

Micromanufacturing is transforming industrial production by enabling the creation of ultra-small components and devices with unprecedented precision. This cutting-edge approach to manufacturing operates at the microscale, producing parts measured in micrometers or even nanometers. As industries demand ever-smaller and more complex components, micromanufacturing is poised to reshape production processes across sectors.

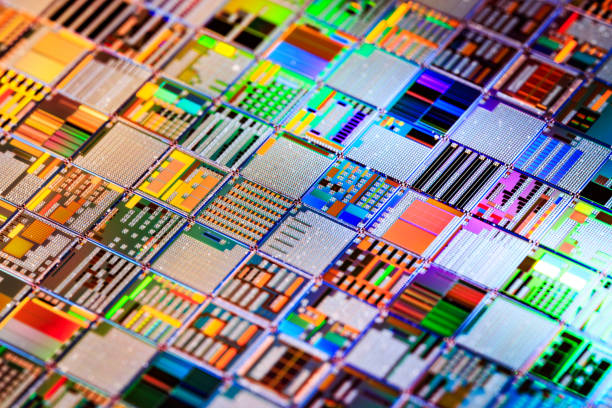

In the 1980s and 1990s, researchers began exploring ways to apply these techniques to other materials and industries. The advent of micro-electromechanical systems (MEMS) further accelerated the field, demonstrating the potential for creating tiny mechanical devices alongside electronic components.

Today, micromanufacturing encompasses a wide range of techniques, from traditional machining scaled down to the micro-level to entirely new processes like two-photon polymerization. This diversity allows for the production of an incredible array of microcomponents, from medical implants to aerospace sensors.

Key Techniques in Micromanufacturing

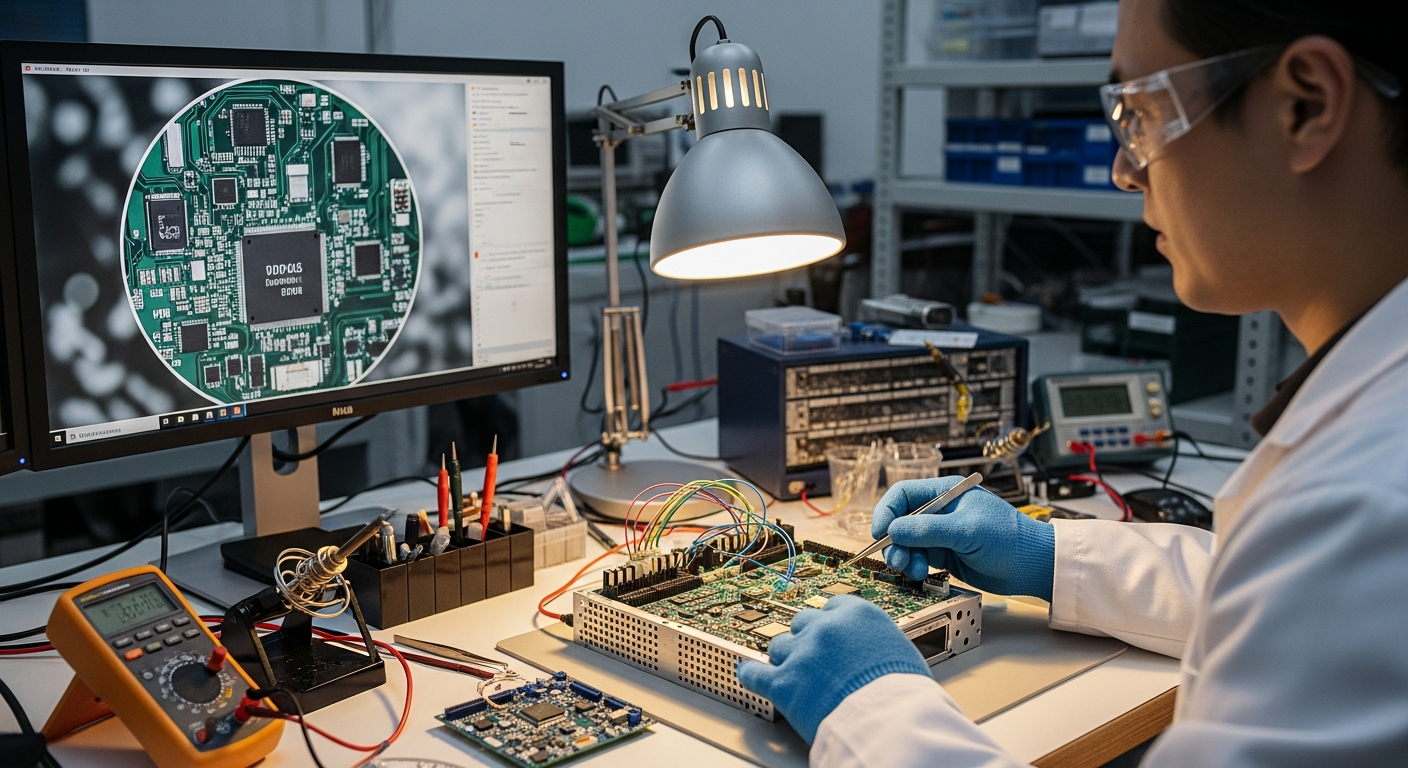

Micromanufacturing employs various specialized techniques to achieve precision at the microscale. One prominent method is micro-milling, which uses ultra-small cutting tools to remove material with micrometer accuracy. These tools, often made of diamond or other ultra-hard materials, can create intricate 3D shapes in metals, polymers, and ceramics.

Another critical technique is micro-injection molding, which adapts traditional plastic molding processes for microscale parts. This method can produce large quantities of identical microcomponents quickly and cost-effectively, making it ideal for mass production of items like microfluidic devices or miniature gears.

Laser-based techniques play a significant role in micromanufacturing as well. Laser micromachining uses focused laser beams to ablate material with extreme precision, allowing for the creation of tiny holes, channels, and surface textures. Two-photon polymerization, a form of 3D printing at the microscale, uses lasers to solidify photosensitive resins, enabling the production of complex 3D structures with features as small as 100 nanometers.

Applications Across Industries

The impact of micromanufacturing is being felt across a wide range of industries. In healthcare, it enables the production of miniature medical devices, such as micro-needles for painless drug delivery, tiny sensors for in-vivo diagnostics, and microfluidic chips for rapid disease detection. These innovations are making medical treatments less invasive and more personalized.

In electronics, micromanufacturing is pushing the boundaries of miniaturization even further. It allows for the creation of microprocessors with ever-smaller transistors, as well as micro-electromechanical systems (MEMS) that integrate sensors, actuators, and electronics on a single chip. These advancements are crucial for the development of smaller, more powerful consumer electronics and IoT devices.

The aerospace and defense sectors are leveraging micromanufacturing to create advanced sensors and components that can withstand extreme conditions while minimizing size and weight. Micro-scale heat exchangers, for instance, can significantly improve thermal management in aircraft and spacecraft.

Challenges and Future Developments

Despite its potential, micromanufacturing faces several challenges. The high precision required often leads to slower production rates compared to traditional manufacturing, impacting scalability. Additionally, the specialized equipment and expertise needed can result in higher costs, particularly for low-volume production.

Quality control is another significant challenge. Inspecting and measuring components at the microscale requires sophisticated metrology techniques, often as complex as the manufacturing processes themselves. Ensuring consistency and reliability across large production runs remains a key area of focus for researchers and industry professionals.

Looking to the future, advancements in artificial intelligence and machine learning are expected to play a crucial role in optimizing micromanufacturing processes. These technologies could help predict and compensate for material behavior at the microscale, improving precision and reliability.

Economic Implications and Market Growth

The micromanufacturing market is experiencing rapid growth, driven by increasing demand for miniaturized components across industries. Market research firms project the global micromanufacturing market to expand at a compound annual growth rate of over 10% in the coming years, reaching billions of dollars in value.

This growth is creating new opportunities for specialized manufacturing firms, as well as driving innovation in equipment and material suppliers. Countries and regions are increasingly recognizing micromanufacturing as a strategic industry, investing in research and development to establish leadership in this high-value sector.

Practical Insights for Businesses Exploring Micromanufacturing

• Start with a thorough cost-benefit analysis, considering both short-term expenses and long-term strategic advantages

• Invest in workforce training to develop the specialized skills required for micromanufacturing

• Explore partnerships with research institutions to stay at the forefront of technological advancements

• Consider outsourcing to specialized micromanufacturing firms before investing in in-house capabilities

• Pay close attention to intellectual property protection, as innovations in this field can be highly valuable

As micromanufacturing continues to evolve, it promises to unlock new possibilities in product design and functionality across industries. By enabling the production of components and devices at scales previously thought impossible, it is driving innovation and opening up new markets. For businesses looking to stay competitive in an increasingly miniaturized world, understanding and leveraging micromanufacturing capabilities will be crucial. The challenges are significant, but so are the potential rewards for those who successfully navigate this microscopic frontier of manufacturing.