Leveraging Technology in Modern Industrial Practices

The industrial sector is undergoing a profound transformation, driven by rapid advancements in technology. From manufacturing floors to global supply chains, digital tools and innovative solutions are reshaping how businesses operate, enhance efficiency, and maintain a competitive edge. Understanding these technological shifts is crucial for companies aiming to optimize their processes, foster innovation, and build resilient operations in an increasingly interconnected world. This article explores key areas where technology is making a significant impact on modern industrial practices, highlighting its role in driving progress and enabling new possibilities across various sectors globally.

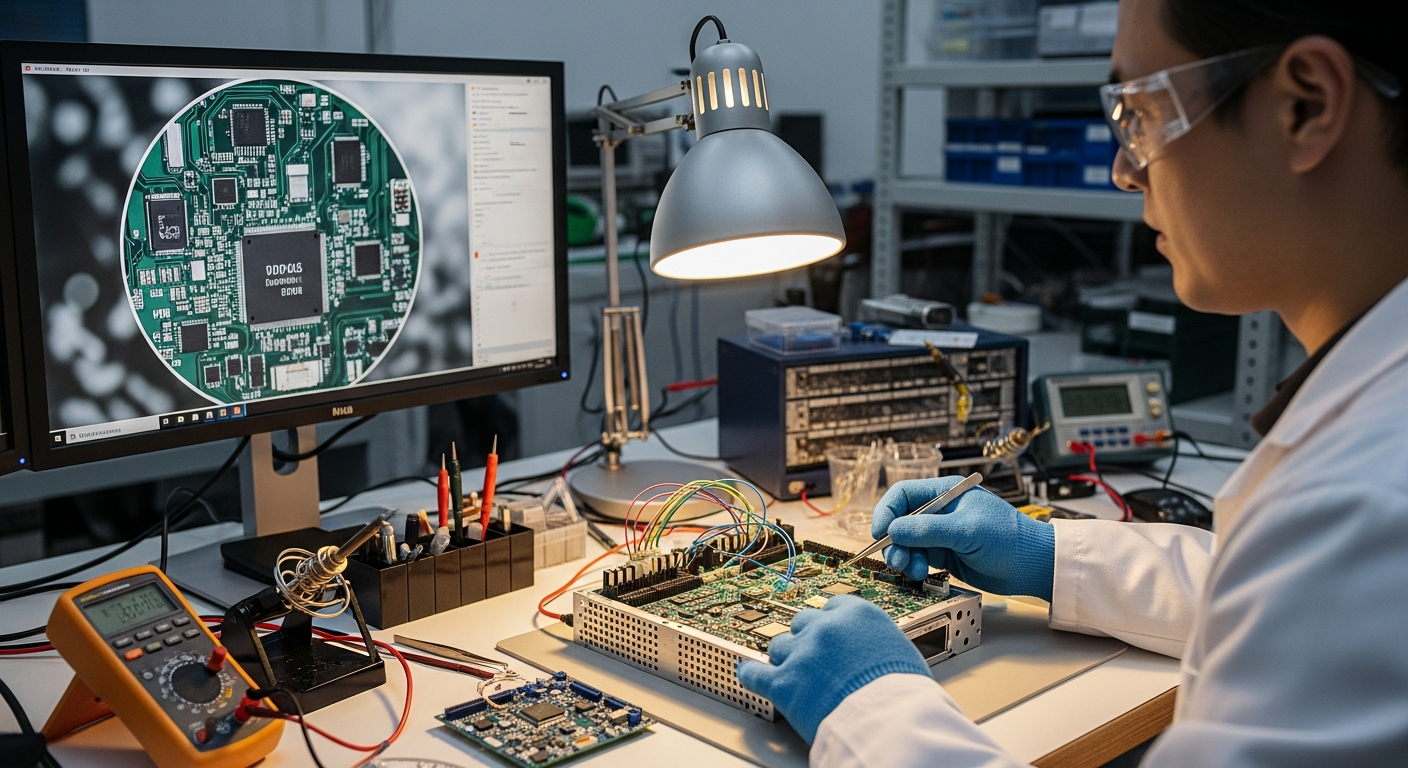

The Role of Digital Technology in Manufacturing

Modern manufacturing is increasingly reliant on digital technology to improve production processes and product quality. The integration of advanced software and hardware, often referred to as Industry 4.0, enables real-time data collection and analysis, predictive maintenance, and highly automated workflows. This shift helps manufacturers achieve greater precision, reduce waste, and accelerate time-to-market. Digitalization also fosters a more agile production environment, allowing companies to respond quickly to market demands and customize products with greater flexibility.

Optimizing Operations and Supply Chain Management

Technology plays a pivotal role in streamlining operations and enhancing supply chain management. Enterprise resource planning (ERP) systems, alongside advanced analytics, provide comprehensive visibility across the entire operational spectrum, from raw material sourcing to final product delivery. This integrated approach allows businesses to identify bottlenecks, optimize inventory levels, and improve decision-making. For logistics, innovations such as real-time tracking, route optimization software, and autonomous vehicles are revolutionizing how goods are transported, leading to reduced costs and faster delivery times across global networks.

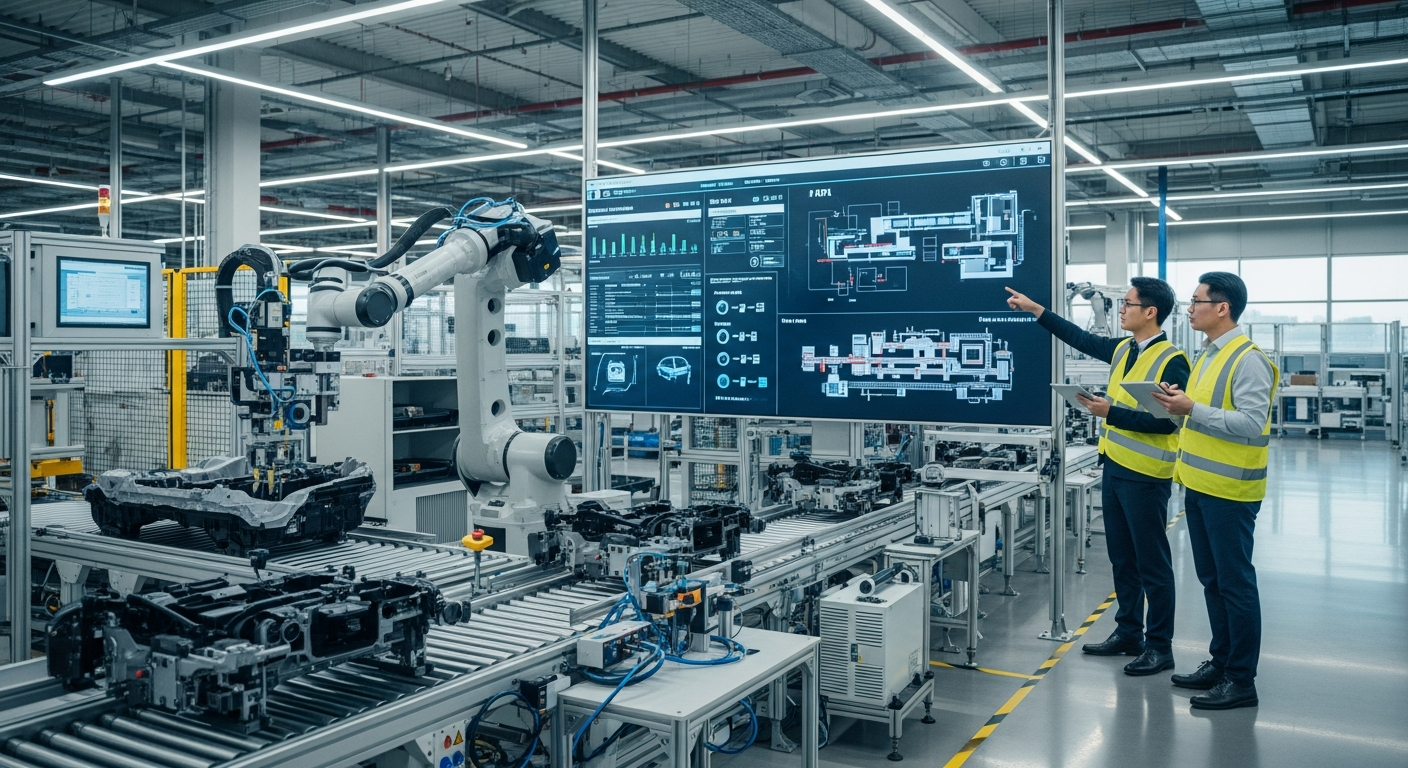

Advancing Efficiency Through Automation and Production Systems

Automation is a cornerstone of modern industrial efficiency, transforming production lines and various operational tasks. Robotic process automation (RPA), collaborative robots (cobots), and automated guided vehicles (AGVs) are becoming commonplace in factories and warehouses. These technologies perform repetitive or hazardous tasks with high accuracy and speed, freeing up human workers for more complex and creative roles. The adoption of advanced production systems not only boosts output but also enhances workplace safety and consistency, contributing significantly to overall operational effectiveness.

Fostering Innovation and Workforce Development

Technological innovation is a continuous driver of development in the industrial landscape. Companies are investing in research and development to explore emerging technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These innovations lead to smarter products, more efficient processes, and entirely new business models. Simultaneously, the evolving technological environment necessitates a focus on workforce development. Training programs that equip employees with digital skills and expertise in new technologies are essential for ensuring a skilled and adaptable workforce capable of navigating the complexities of modern industrial practices.

Building Resilience and Sustainability in Industry

In an era of increasing global challenges, technology is instrumental in building resilience and promoting sustainability within industry. Predictive analytics and digital twins allow companies to simulate scenarios and anticipate potential disruptions, enhancing their ability to respond effectively to unforeseen events. Furthermore, technologies designed for energy efficiency, waste reduction, and circular economy principles are helping industries minimize their environmental footprint. From smart grids to advanced recycling processes, digital tools are enabling more sustainable practices, contributing to both ecological responsibility and long-term economic viability. This focus on sustainability also resonates with consumer demand and global markets, reinforcing the need for responsible industrial practices.

Technological advancements are fundamentally reshaping the industrial landscape, offering unprecedented opportunities for growth, efficiency, and sustainability. By embracing these innovations, businesses can navigate complex global markets, enhance their production capabilities, and cultivate a resilient and forward-thinking enterprise. The continuous integration of digital tools and automation will remain critical for companies aiming to thrive in the dynamic environment of modern industry.